A1351

High Precision Linear Hall Effect Sensor IC

with a Push/Pull, Pulse Width Modulated Output

17

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

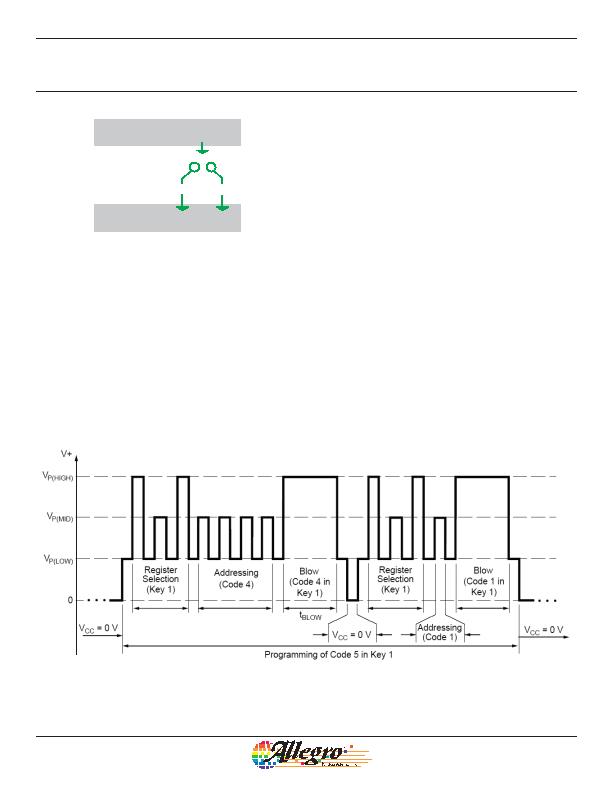

(Decimal Equivalent)

Code 5

Bit Field Selection

Address Code Format

Code in Binary

Fuse Blowing

Target Bits

Fuse Blowing

Address Code Format

(Binary)

1 0 1

Bit 2

Bit 0

Code 4 Code 1

(Decimal Equivalents)

Figure 3. Example of code 5 broken into its binary components,

equaling code 4 and code 1.

Locking the Device

After the desired code for each parameter is programmed, the

device can be locked to prevent further programming of any

parameters. See the Lock Mode section for lock pulse sequence.

Additional Guidelines

The additional guidelines in this section should be followed to

ensure the proper behavior of these devices:

" A 0.1 糉 blowing capacitor, C

BLOW

, must be mounted between

the PWMOUT pin and the GND pin during programming, to

ensure enough current is available to blow fuses.

" The final application capacitance, C

L

, should be used when

measuring the output duty cycle during programming. (The

maximum load capacitance is 14.7 nF for proper operation.)

" The blowing capacitor, C

BLOW

, should be removed during

measurements; it should only be applied when addressing bit

fields and when blowing fuses.

" The power supply used for programming must be capable of

delivering at least 26 V and 300 mA.

" Be careful to observe the t

LOW

delay time before powering

down the device after blowing each bit.

" The following programming order is recommended:

1. PWM carrier frequency

2. Coarse D

(Q)

3. Sens

4. D

(Q)

5. LOCK (only after all other parameters have been

programmed and validated, because this prevents any further

programming of the device)

Figure 4. Example of programming pulses applied to the PWMOUT pin that result in permanent parameter settings. In this example, the register

corresponding to key 1 is selected (twice) and code 5 is addressed and blown (in two stages).

发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

A1354KKT-T

IC SENSOR HALL EFFECT 4-SIP

A1356LKB-T

IC SENSOR HALL EFFECT 3 SIP

A1361LKTTN-T

IC HALL EFFECT SENSOR LN 4-SIP

A1374EKB-T

IC SENSOR HALL EFFECT PREC 3-SIP

A1422LK

IC SENSOR HALL EFFECT AC 4-SIP

A1425LK

IC SENSOR HALL EFFECT AC 4-SIP

A1645LK-I2

IC SENSOR HALL EFFECT AC 4-SIP

A3230LUA-T

IC SW HALL EFFECT CHOPPER 3-SIP

相关代理商/技术参数

A1352-035

制造商:AVX Corporation 功能描述:

A1352-037

制造商:AVX Corporation 功能描述:

A13532-43N

制造商:Harris Corporation 功能描述:

A1354

制造商:ALLEGRO 制造商全称:Allegro MicroSystems 功能描述:High Precision 2-Wire Linear Hall Effect Sensor IC with Pulse Width Modulated Output

A13546-000

制造商:TE Connectivity 功能描述:VARISTOR 680V 20MM RADIAL 制造商:TE Connectivity 功能描述:VARISTOR 680V 10KA DISC 20MM 制造商:TE CONNECTIVITY RAYCHEM-POLYSWITCH 功能描述:Var MOV 420VAC 560VDC 10000A 680V Thru-Hole Bulk

A1354KKT-T

功能描述:IC SENSOR HALL EFFECT 4-SIP RoHS:是 类别:传感器,转换器 >> 磁性 - 霍尔效应,数字式开关,线性,罗盘 (IC) 系列:- 标准包装:1 系列:- 传感范围:20mT ~ 80mT 类型:旋转 电源电压:4.5 V ~ 5.5 V 电流 - 电源:15mA 电流 - 输出(最大):- 输出类型:数字式,PWM,8.5 位串行 特点:可编程 工作温度:-40°C ~ 150°C 封装/外壳:20-SSOP(0.209",5.30mm 宽) 供应商设备封装:20-SSOP 包装:Digi-Reel® 其它名称:AS5132-HSST-500DKR

A1354KKTTN-T

功能描述:IC HALL EFFECT SENSOR 2WIRE 4SIP RoHS:是 类别:传感器,转换器 >> 磁性 - 霍尔效应,数字式开关,线性,罗盘 (IC) 系列:- 标准包装:1 系列:- 传感范围:20mT ~ 80mT 类型:旋转 电源电压:4.5 V ~ 5.5 V 电流 - 电源:15mA 电流 - 输出(最大):- 输出类型:数字式,PWM,8.5 位串行 特点:可编程 工作温度:-40°C ~ 150°C 封装/外壳:20-SSOP(0.209",5.30mm 宽) 供应商设备封装:20-SSOP 包装:Digi-Reel® 其它名称:AS5132-HSST-500DKR

A1354P1-2

制造商:APEM 功能描述: